From billet to profile

Our extrusion press in Pierrefitte Nestalas (France) and our brand new factory in Portugal can handle any type of extrusion project for very long lengths.

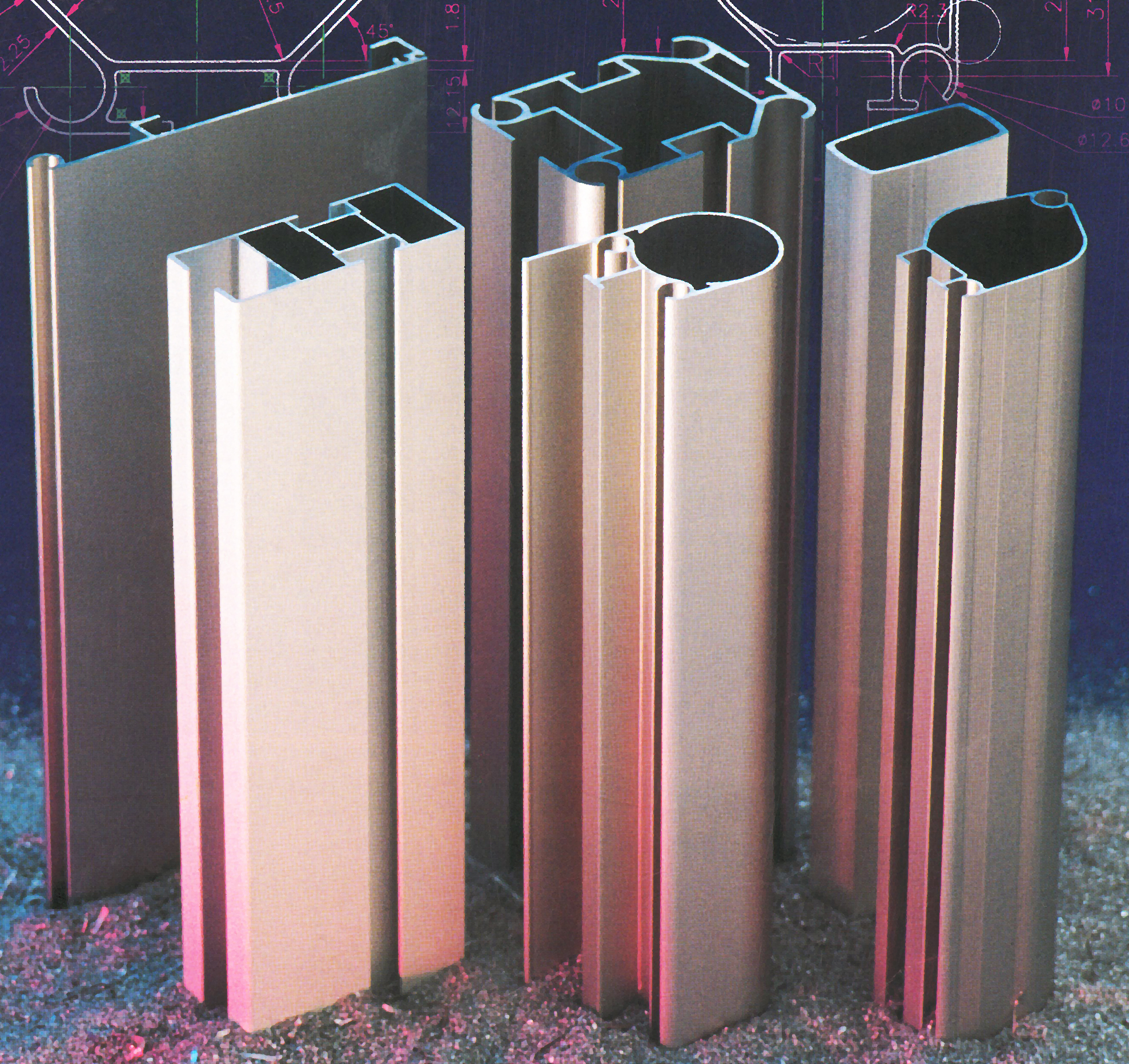

Extrusion involves pushing a material to be fluidised through a die. This material may be metal or plastic. The result is a long product that will be used in the composition of an object or structure.

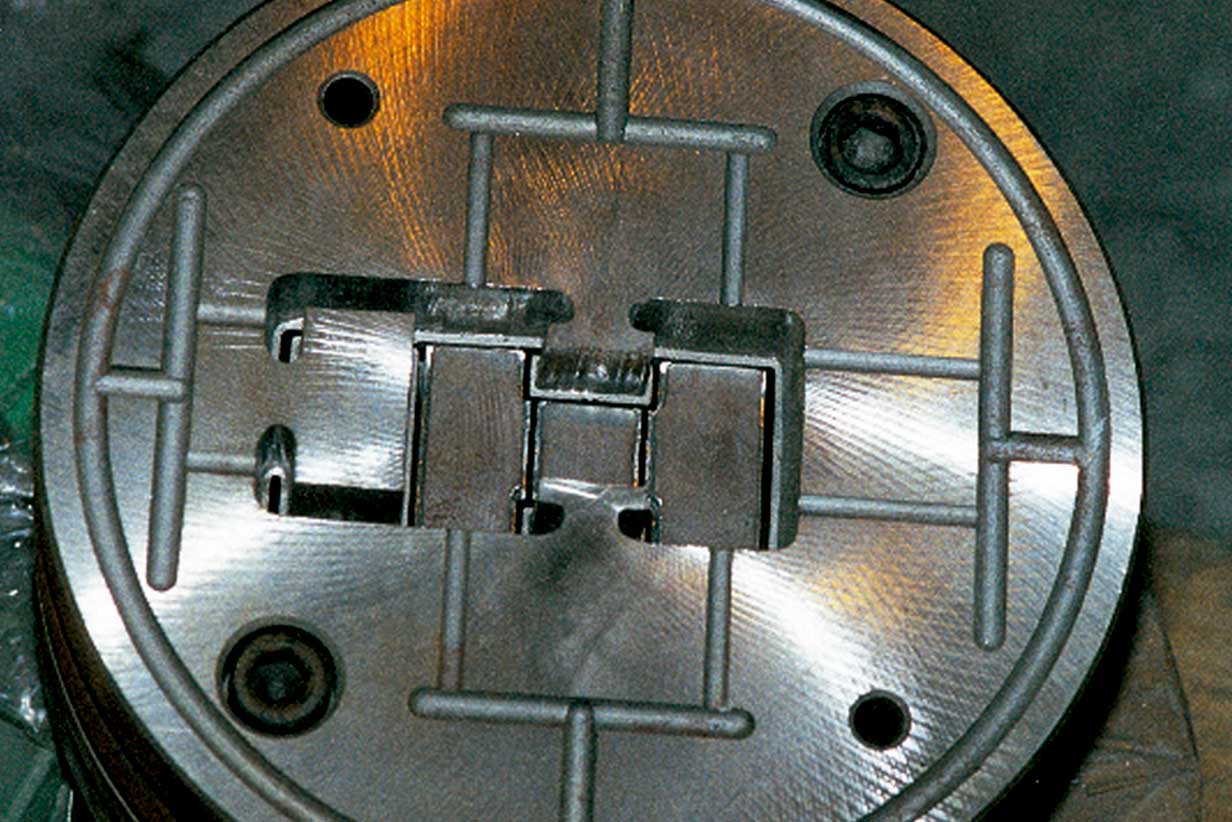

What is aluminium extrusion? It is a thermomechanical production process. Under pressure, a compressed material (in this case aluminium) is forced through a die shaped to the desired profile. This produces a continuous long product which is then cut to the dimensions required by the customer. The result obtained on the cooling and stretching table can be tubular or solid.

A billet, a compressed, solid cylinder heated to at least 500°C, is placed in a hollow container and pushed through to become what is known as a ‘profile’.

The video opposite shows the aluminium extrusion process, which is essential to the production of our products.

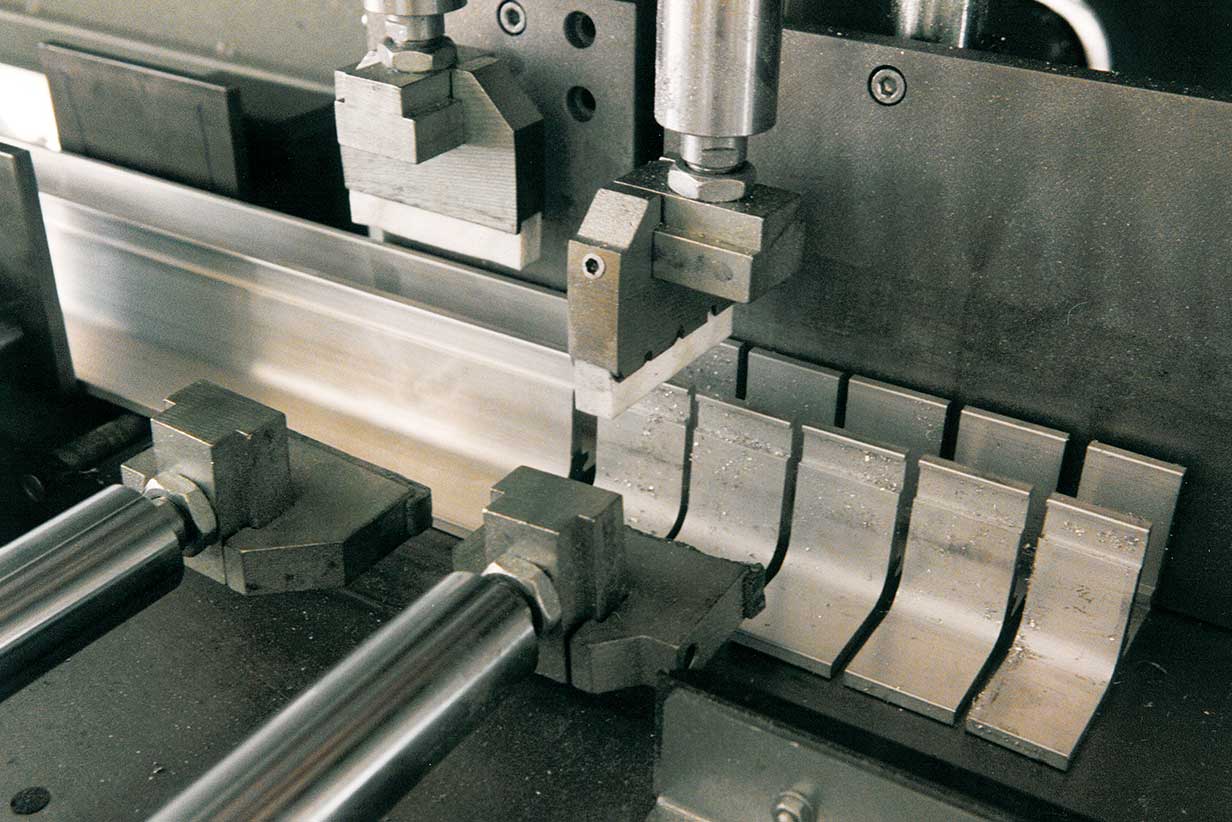

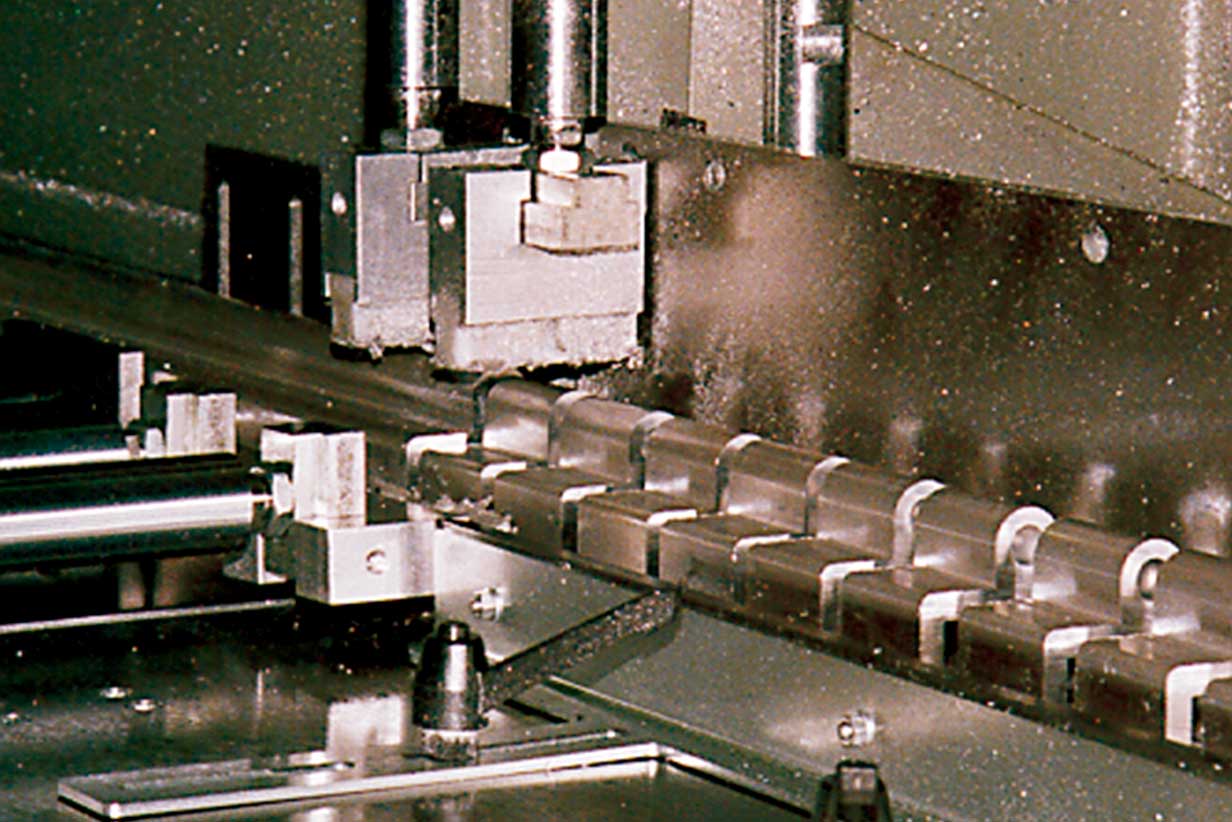

Cutting and mechanization of extruded parts

Profile extrusion also allows numerous extruded parts to be produced thanks to mechanisation.

This is often an economical solution for many manufactured products. In addition, the parts have excellent surface finishes.

Mechanisation is coupled with numerous tests at the end of the extrusion process to prevent deformation in particular. All this is part of our quality approach throughout the production process.

NEW ALLIANCE

For our aluminium profiles

Our new aluminium alloy contains more silicon, iron, copper and magnesium, giving it 25% greater bending strength than the previous standard alloy.

This solution is more suitable for use with long profiles, such as front bars, cassettes and maxi arms.

Our factory is therefore able to satisfactorily meet our customers’ demands.

Do you have an aluminium project?

Need a partner for aluminium extrusion? Request a quote? Our group’s production facilities across Europe offer significant production capacity. We will assess your project. Contact us!